Kucha products

Build quality reliability through integrated modularity

Warehouse fork module forklift

Kucha Modular Forklift is an electric forklift that adopts modular design thinking. It can split the entire forklift into two standard modules: a front frame and a rear operating rod. The front frame adopts market standard universal frame (or non-standard customized frame), which is compatible with various frame functions and achieves universal adaptability between modules; The rear operating lever integrates complete electrical functions, which can achieve different functions such as lifting, tilting, or lateral movement according to the frame function, plug and play, convenient and flexible.

TO2 integrated AI drive rod+frame

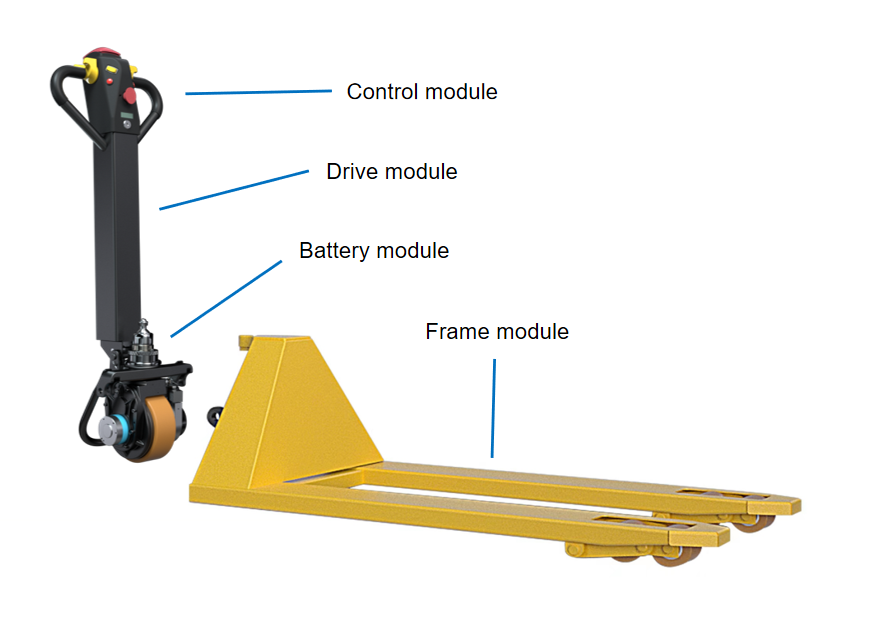

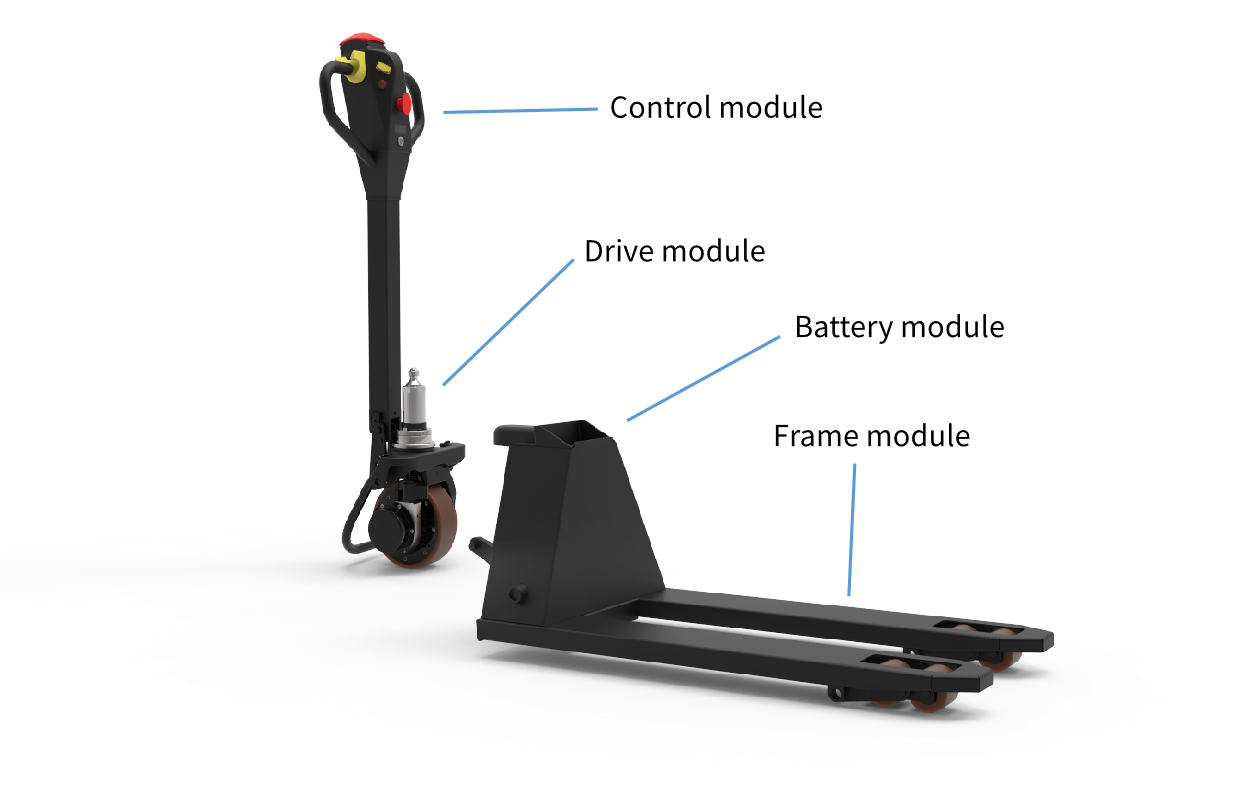

The control module, energy module, drive module, and frame module together form the forklift with a storage fork and module

Control module

The control module integrates complete control functions, including: forward and backward displacement function; Hydraulic function for ascending and descending; Emergency braking, safety braking in case of power loss, high torque for starting and climbing, auxiliary parking on half slopes, and other functions. Equipped with a turtle speed, charging port, speaker, main power switch, and the ability to configure a Bluetooth key, truly achieving mobile phone management.

Energy module

The T02 model integrated pole adopts A-level battery cells, which are safer and more reliable. According to different endurance requirements, 48V10AH, 48V15AH, or 48V20AH batteries can be selected.

The T03 model integrated pole does not come with its own battery, and the battery compartment is located outside the frame, making it more lightweight and convenient to use.

Drive module

The drive module is a motor that can achieve walking drive, lifting drive, and magnetic braking. It is equipped with a fully functional hydraulic kit and a reduction gear set, with a simple structure and long-lasting durability. The motor can be freely equipped with different powers ranging from 600W to 1200W, achieving different load requirements.

Frame module

Adopting a simple and durable riveting structure, it can be quickly replaced. Customized according to usage scenarios, compatible with general manual forklift frames on the market, and providing unlimited possibilities for upgrading electric forklifts to manual forklift frames. Provide flexible choices and personalized configurations.

TO3 integrated AI drive rod+frame

Module accessories recommendation

Diversified products, there is always one that suits you

Driven by customer needs and product development philosophy